Prototype fabrication is a procedure wherein personalized and accurate metal parts are being made in order to evaluate and perfect a certain product design prior to mass production. This is a fundamental practice in fields like aerospace, automotive, and medical devices, where every component is required to meet specific benchmarks for performance and reliability.

Metal Prototyping Key Secrets

Custom Metal Prototypes Fabrication is a field where a collection of state-of-the-art techniques prevail, and this is dependent on the project requirement in terms of detail, strength as well as material properties.

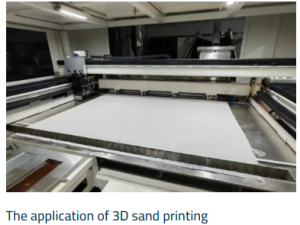

3D Printing (Metal Additive Manufacturing) – This technique builds parts up layer by layer from metal powder. The technology allows unattainable complex geometries by conventional means completely new design approaches it makes possible. 3D printing allows the production of components with complex internal features, retaining structural integrity down to a fine (sub-mm) level of tolerance.

CNC Machining — this is a subtractive process in which takes a solid metal block and machines it down to the desired shape using computer-controlled tools. Known for extreme precision that provides tolerances as close as 0.0005 inches, this is essential for high performance, fit critical parts.

Sheet metal fabrication – Cutting and bending the sheets of metal to create parts. For larger production runs, precision and repeatability can be achieved using techniques like stamping, bending, and laser cutting.

Materials Making a Difference

The selection of material is of great importance in the operation and use of prototypes,

Aluminum —Lightweight and strong, used almost exclusively for automotive and aerospace prototypes due to its high durability and light weight ratio.

Stainless Steel, ideal for its high strength and corrosion resistance, stainless steel is used for medical devices, food processing equipment, etc.

Titanium: Provides a nearly identical strength, weight, and is valuable to aerospace and military applications as the best-in-class alloy with the top strength-to-weight ratio.

Use-Cases for Impact and Real-World Benefits

With rapid prototyping of metal parts, designers and engineers bring prototypes for functional testing to validate designs and functionalities efficiently. Due to prototyping of new components in the automotive division, it helps in testing and optimising the components that will be used in the car in order to increase the safety and performance. Custom prototypes of new surgical instruments or implants can be tested in medicine, ensuring new innovations offer true patient benefits before full-scale production guiActive

A high-profile industry example is a top aerospace firm that used titanium prototypes in developing a jet engine component and saw a weight reduction of 30%, leading to a 25% increase in fuel efficiency. This shows the technical ability of new prototyping techniques and also how they can drastically advance overall product performance and industry movement.

Accelerated Innovation and Efficiency

Metal Prototypes fabrication is not just about making parts, it is a crucial practice that stimulates advancement throughout the sectors. This allows companies to outpace the competition by going faster in competitive markets at a pace of development far superior to it as they get immediate feedback from the end users of the improvements they rolled out. A proactive design and testing model prevents products from being rushed to the market without regard for safety or effectiveness.